ASTM B348/ASTM B863 Gr. 1 & Gr. 2 Titanium Wire for Spherical Nano Powder and Micro Powder

Spherical powders with good flowability are interesting for this process because they can be fed more easily at a constant rate. Thermal spray usually requires powders with fine particle size distribution because short residence time in the hot zone can only melt efficiently particles below 45 microns.

Highly spherical powders are ideal for AM which requires excellent flowability and high density uniform packing. A high level of purity of the metallic powders is also critical to reach good mechanical properties and to allow the powder to be recycled many times.

Given the above benefits and constant progress in the performance and productivity of the equipment, additive manufacturing is rapidly developing in Europe, North America and Asia.

Highly spherical powders are ideal for AM which requires excellent flowability and high density uniform packing. A high level of purity of the metallic powders is also critical to reach good mechanical properties and to allow the powder to be recycled many times.

Baoji Titanium Wire Industry Co., Ltd. is able to manufacture CP-Ti and Alloyed titanium wire for spherical powder and micropowder.

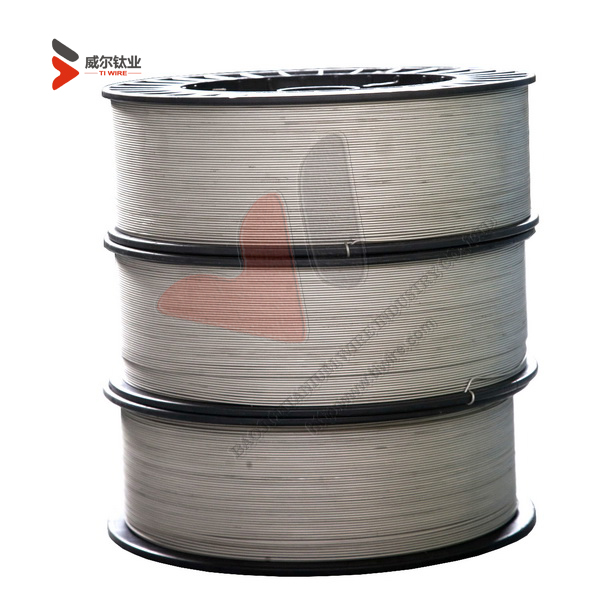

Product specifications:

Diameter: 3.175mm, 6.35mm

Weight: about 50kg per coil

Shape: in coil

Surface treatment: Pickled and peeled

Grade status: Gr. 1, Gr. 2

Standards: ASTM F67, ASTM B863, ASTM B348

Applications:

Medical and dental devices

Aerospace

Consumer goods

Design/architecture

Tooling

Robotics

Automotive

Defense

Motor sports

Fashion industry

Annual capability:

600MT

Packing:

In coil: protected by foam paper + plywood case

Delivery lead-time:

5-15 days

Shipping:

By international express (TNT, FedEx, DHL, UPS), by air, sea

Trade terms:

FOB China, CIF and DDP

Payment terms:

T/T, L/C, PayPal, Western Union

![]() TESTING REPORT FOR GR.1&2 ELI (MICRO POWDER).pdf

TESTING REPORT FOR GR.1&2 ELI (MICRO POWDER).pdf

ASTM B348/ASTM B863 Gr. 1 & Gr. 2 Titanium Wire for Spherical Nano Powder and Micro Powder

1. Product designation:

Titanium wire Grade 1 & Grade 2

2. Chemical composition:

| Element | Gr.1 (wt.%) | Gr.2 (wt.%) | Testing Method | ||||||

| Oxygen (O) | 0.10-0.18 | 0.18-0.25 | ASTM E1409 | ||||||

| Nitrogen (N) | 0.02 | 0.02 | ASTM E1409 | ||||||

| Carbon (C) | 0.02 | 0.02 | ASTM E1941 | ||||||

| Hydrogen (H) | 0.01 | 0.01 | ASTM E1447 | ||||||

| Iron (Fe) | 0.05-0.30 | 0.05-0.30 | ASTM E2371 | ||||||

| Other elements, each | 0.1 | 0.1 | ASTM E2371 | ||||||

| Other elements, total | 0.4 | 0.4 | ASTM E2371 | ||||||

| Titanium (Ti) | Balance | Balance | ASTM E2371 | ||||||

Chemical analysis of the wire shall be done according to the requirements of ASTM B348, ASTM F67, ASTM F1580 and ASTM B863 | |||||||||